A digital mass flowmeter is an instrument that directly measures the mass flow rate of a fluid (liquid, gas, or steam) as it passes through a pipe, providing the data as a digital output. Unlike volumetric flow meters, mass flow measurements are not affected by changes in fluid properties like pressure, temperature, or density, making them highly accurate for critical applications.

Key Features and Benefits

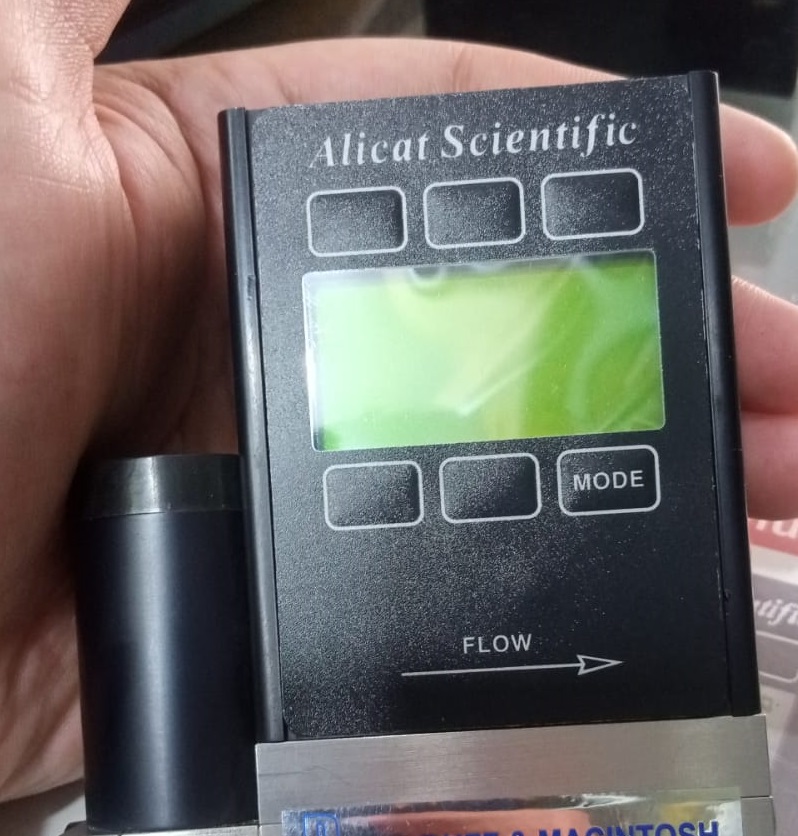

Digital mass flowmeters typically include a sensor, a transmitter for converting sensor signals to digital data, a display unit, a power supply, and a communication interface (e.g., Modbus, HART).

- High Accuracy: They provide highly accurate measurements as they directly measure mass, which is a constant property, unlike volume, which can change with temperature and pressure.

- Real-time Monitoring: Digital displays and data output capabilities (e.g., RS485, Ethernet) allow for continuous, real-time monitoring and integration into control systems.

- Versatility: Specific models can measure both liquids and gases (Coriolis), or are specialized for gas flow (thermal), and can often handle a range of challenging conditions like high temperatures and pressures.

- Reliability: With no moving parts in many designs (Coriolis and thermal), they typically require less maintenance compared to traditional mechanical flow meters.